Conical header tanks and manifolds

Protocol for making conical header tanks and manifolds

Materials & Equipment

| Item | Quantity per system | Purpose | |

|---|---|---|---|

| A. Cooler (120 qt) | 1 | Header tank | |

| B. Float valve | 1 | Float valve for water input to header | |

| C. ¾” barb nylon fitting (garden hose thread) | 1 | Fitting for water tubing to float valve | |

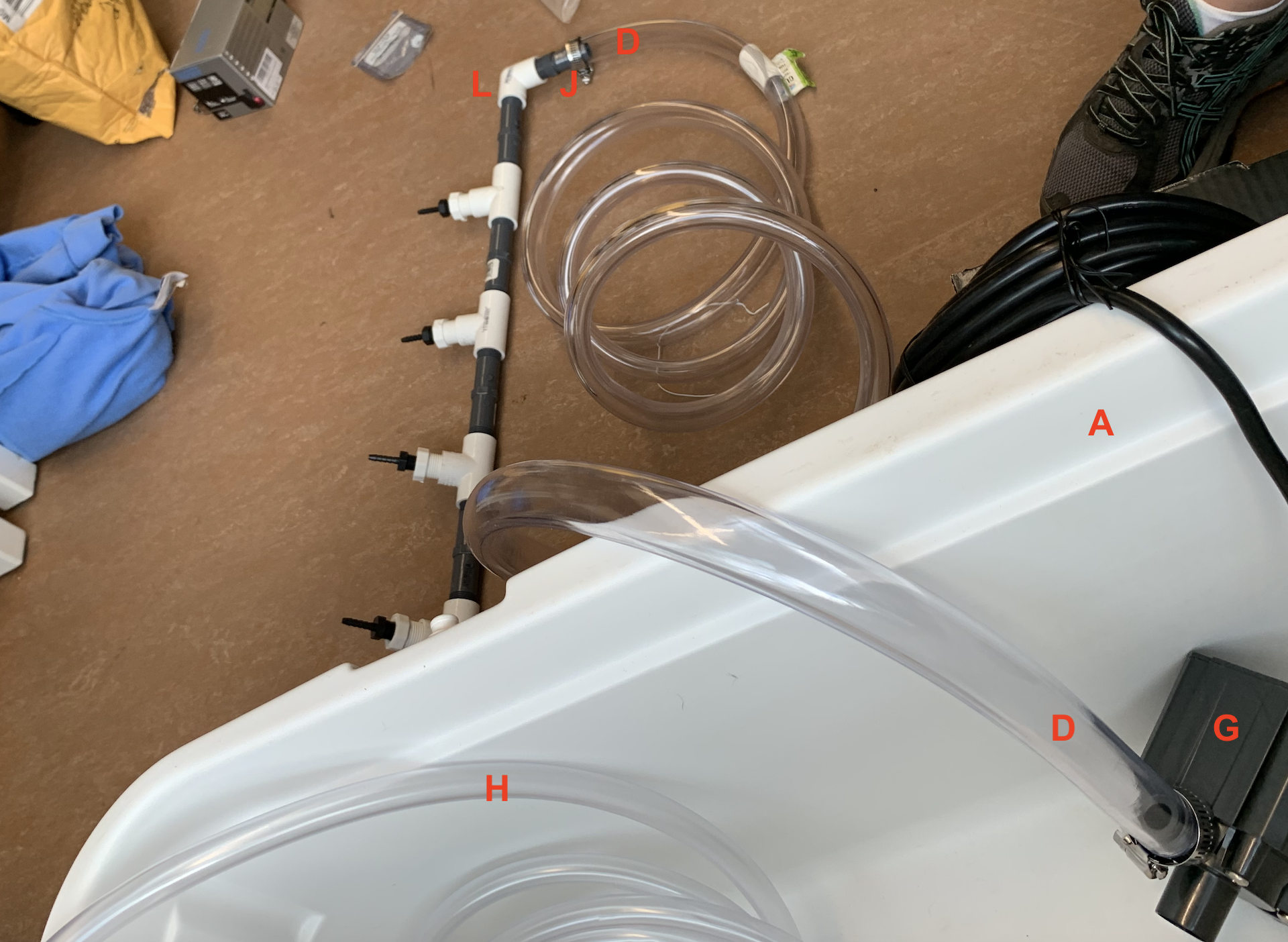

| D. ¾” interior diameter tubing (10ft) | 1 | Tubing for water input | |

| E. Stainless steel tubing clamps | 8 | Secure tubing | |

| F. Teflon tape | 2 | Sealing connections | |

| G. Mag Drive pump (Model 2) | 1 | Delivery pump | |

| H. ½” interior diameter tubing (10ft) | 1 | Tubing from header to PVC manifold | |

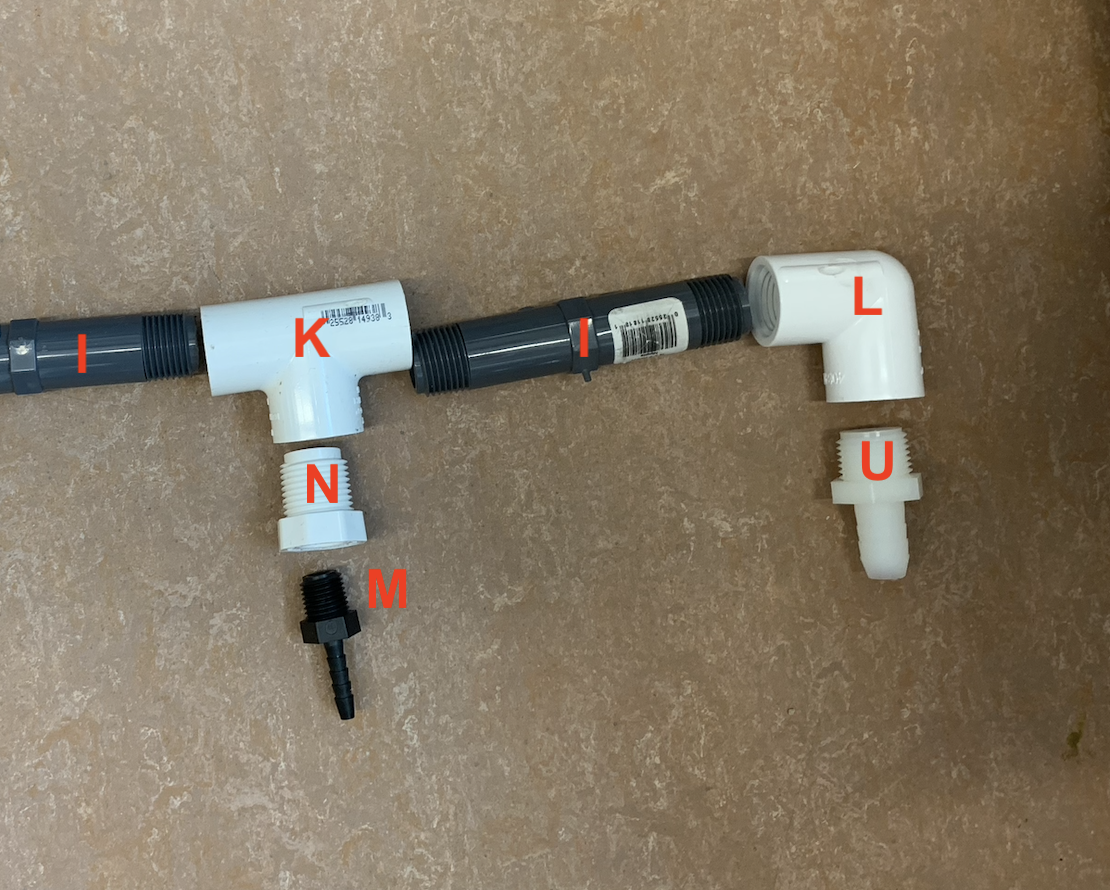

| I. ½” PVC nipple fittings 4” | 7 | Manifold for delivery system | |

| J. ¾” to ½” barb fitting | 1 | Attach tubing to manifold | |

| K. ½” PVC Tee’s (thread-thread-thread) | 6 | Manifold outlets | |

| L. Elbow thread-thread ½” PVC | 2 | Attach tubing to manifold | |

| M. 1/4” to 3/16” threaded barbs (part 5218K684) | 6 | Attach tubing to manifold and conicals | |

| N. ½” to ¼” pvc threaded reducer | 6 | Attach tubing barbs to manifold | |

| O. 3/16” silicon tubing (100 ft) | 1 | Tubing to conicals | |

| P. Spring clamps 2-in | 3 | Hold PVC manifold to tanks | |

| Q. Stainless Steel Nuts | 6 | Attach to loggers | |

| R. Roller tubing clamps (white, plastic) | 6 | Regulating conical flow | |

| S. Zip ties (assorted sizes) | 1 | General use | |

| T. ½” PVC threaded caps | 1 | Cap manifolds if needed | |

| U. ½” barb threaded fittings | 2 | Attach return tubing | |

| V. 153um plankton mesh | 1 | Mesh for banjo filters (~1 yard per system) | |

| W. 500W heaters | 2 | Heaters for header tank (either 500W or 800W) | |

| X. 4” PVC (will need to be cut into slices) (2 ft) | 2 | Banjo filters | |

| Y. 1 1/4” PVC (10 ft) | 1 | Banjo filters | |

| Z. 1 1/4” PVC elbow slip fitting | 6 | Banjo filters | |

| AA. 1 ¼” PVC straight slip fitting | 6 | Banjo filters | |

| BB. Hot glue and/or sealant | 1 | Secure banjo filters | |

| CC. Bag filter 100um 7x18” | 2 | Filter attached to float valves |

Size of materials can be adjusted to fit specific systems.

Protocol

Before proceeding, make sure all materials are acquired and in the correct size and quantity.

Manifold

Full manifold

Close-up of water entry side of manifold

Close-up of water outflow side of manifold

Close-up of Tee and barb fittings

Header tank

Float valve with tubing

Mag-pump in cooler

Mag-pump attached to manifold

Close-up of manifold and tubing from Mag-pump connection

Close-up of manifold and outflow tubing

Written on August 30, 2021